Reputable Industrial Scales Constructed for Heavy-Duty Applications

Reputable Industrial Scales Constructed for Heavy-Duty Applications

Blog Article

Enhance Your Business Workflow With Reliable Industrial Scales

In today's competitive landscape, the precision of commercial scales plays a crucial function in boosting general business procedures. Accurate evaluating not only mitigates pricey discrepancies throughout various markets, such as manufacturing and logistics, yet also makes certain compliance with rigid market criteria. As companies look for to optimize effectiveness, understanding the different sorts of scales and their technological advancements comes to be essential. Nevertheless, the option process can be complicated, and the effects of these choices can dramatically affect operational success. What aspects should be considered to guarantee the right devices is selected for your certain demands?

Relevance of Accurate Considering

Exact considering is crucial in various industrial applications, as also minor inconsistencies can result in considerable financial losses and operational inefficiencies. Industries such as manufacturing, logistics, and food handling rely on precise measurements to ensure product top quality, governing conformity, and ideal resource management. Imprecise weights can lead to overproduction, wastage of resources, or poor supply, affecting success and customer fulfillment.

Furthermore, accurate considering is essential for safety and ecological compliance. In the chemical market, wrong measurements can lead to improper combinations, resulting in unsafe circumstances or lawful ramifications. In the food industry, exact weighing is important for sticking to nutritional labeling demands, ensuring that consumers obtain accurate info regarding the products they acquire.

The integration of dependable industrial ranges not just improves operational performance yet likewise supports data-driven decision-making. Spending in top notch commercial evaluating solutions is important for businesses intending to preserve a competitive side in today's dynamic marketplace.

Sorts Of Industrial Scales

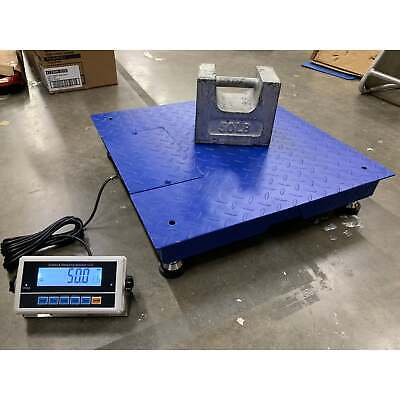

Industrial ranges are available in various kinds, each created to satisfy particular weighing demands across different fields. Amongst the most common types are system scales, which provide a big weighing surface area appropriate for heavy things, making them ideal for stockrooms and making facilities. These ranges typically feature electronic display screens for easy analysis.

Another kind is bench ranges, which are usually smaller and mobile, excellent for use in laboratories or retail atmospheres. They permit quick dimension of smaller things while preserving precision. For applications needing the weighing of fluids, container ranges are especially created to measure the weight of tank, making sure precise supply management.

In addition, floor scales are made use of for weighing hefty tons on the ground degree, frequently made use of in shipping and getting divisions. Crane ranges are also notable; they are put on hold from a framework to weigh heavy products in industrial settings. Load cells play a vital duty in many scales, converting pressure into an electric signal for accurate weight measurement. Each type of industrial range offers an one-of-a-kind function, improving functional performance across diverse industries.

Advantages of Modern Modern Technology

Additionally, contemporary commercial scales typically come furnished visit this web-site with connectivity functions that allow seamless combination with other systems, such as inventory management and manufacturing monitoring. This interconnectivity promotes a much more cohesive workflow and blog here minimizes downtime, as organizations can check efficiency metrics and make data-driven choices quickly.

Additionally, many modern ranges provide adjustable settings and user-friendly user interfaces, enabling operators to adjust their devices for particular operational needs. Boosted longevity and strength against severe ecological conditions even more contribute to the long life and integrity of contemporary scales, guaranteeing they can hold up against the rigors of industrial usage.

Selecting the Right Equipment

Different industries may call for distinctive sorts of scales, such as floor scales for hefty tons, bench scales for smaller things, or portable ranges for versatility. Furthermore, considering the setting in which the ranges will be used is essential. For example, devices used in harsh settings might need to be rugged and immune to dirt, wetness, or extreme temperature levels.

One more crucial variable is the innovation utilized in the ranges. Digital scales commonly use enhanced accuracy and simplicity of usage, while analog ranges might suffice for much less requiring applications. It is important to assess the scalability of the tools, ensuring that it can fit future development or changes in production procedures.

Lastly, companies must take into consideration find more the credibility and dependability of suppliers, as buying premium tools can lead to long-term expense financial savings and boosted functional effectiveness.

Maintenance for Durability

Routine upkeep is crucial for making sure the longevity and optimal performance of industrial scales. A systematic method to maintenance not only prolongs the life of the devices however likewise ensures precise measurements important for functional effectiveness.

Begin with routine evaluations to determine deterioration, guaranteeing components such as load cells and displays function appropriately. Calibration checks need to be performed routinely, ideally after substantial adjustments in ecological conditions or following heavy use. Precise calibration is crucial for compliance with industry criteria and for preserving the dependability of weight measurements.

Cleaning is an additional essential facet of maintenance. Dust, particles, and destructive substances can impair efficiency and cause inaccuracies. Usage proper cleaning agents and strategies to safeguard sensitive parts. In addition, it is a good idea to establish an upkeep routine that records each solution check out, calibration, and any fixings done. This paperwork help in tracking equipment efficiency and planning for future upkeep needs.

Lastly, educating staff on appropriate use and care methods will certainly reduce the chance of operator error, better enhancing range integrity. By prioritizing routine upkeep, businesses can make sure that their commercial scales remain a trustworthy asset in their operations.

Final Thought

In summary, the combination of reputable industrial scales is vital for improving company operations across various fields. Normal upkeep and training further contribute to the longevity and precision of these ranges, promoting data-driven decision-making and eventually supporting total organization success.

Industrial ranges come in different types, each made to fulfill certain weighing needs throughout different sectors. Crane ranges are likewise notable; they are put on hold from a framework to consider heavy products in commercial settings.Various markets may call for unique kinds of ranges, such as floor ranges for heavy lots, bench scales for smaller things, or portable ranges for versatility - Industrial Scales. Digital ranges usually use enhanced precision and ease of usage, while analog scales might be enough for much less demanding applications.In recap, the integration of trusted industrial ranges is vital for enhancing service operations across numerous industries

Report this page